Services

3DnA is an engineering company focused on additive manufacturing technologies that offers an integrated service of design, optimization, simulation, prototyping, and production, utilizing industrial additive printing systems.

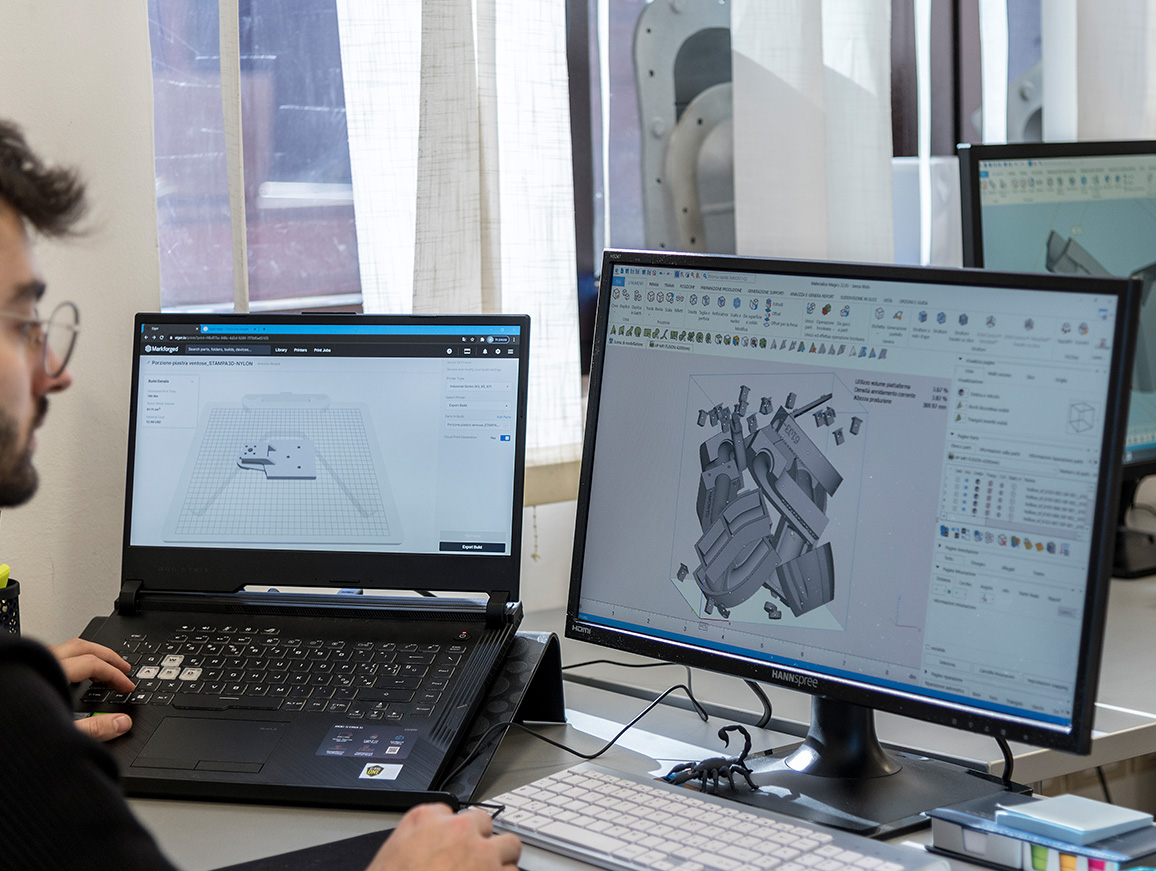

Design

Our design service offers the expertise of experienced engineers and designers who work closely with clients to transform their ideas into tangible realities. We use the most advanced CAD software, 3D modeling techniques, or reverse engineering using advanced 3D scanners to create customized designs and products that meet the client’s specific needs, whether for a single prototype or large-scale production.

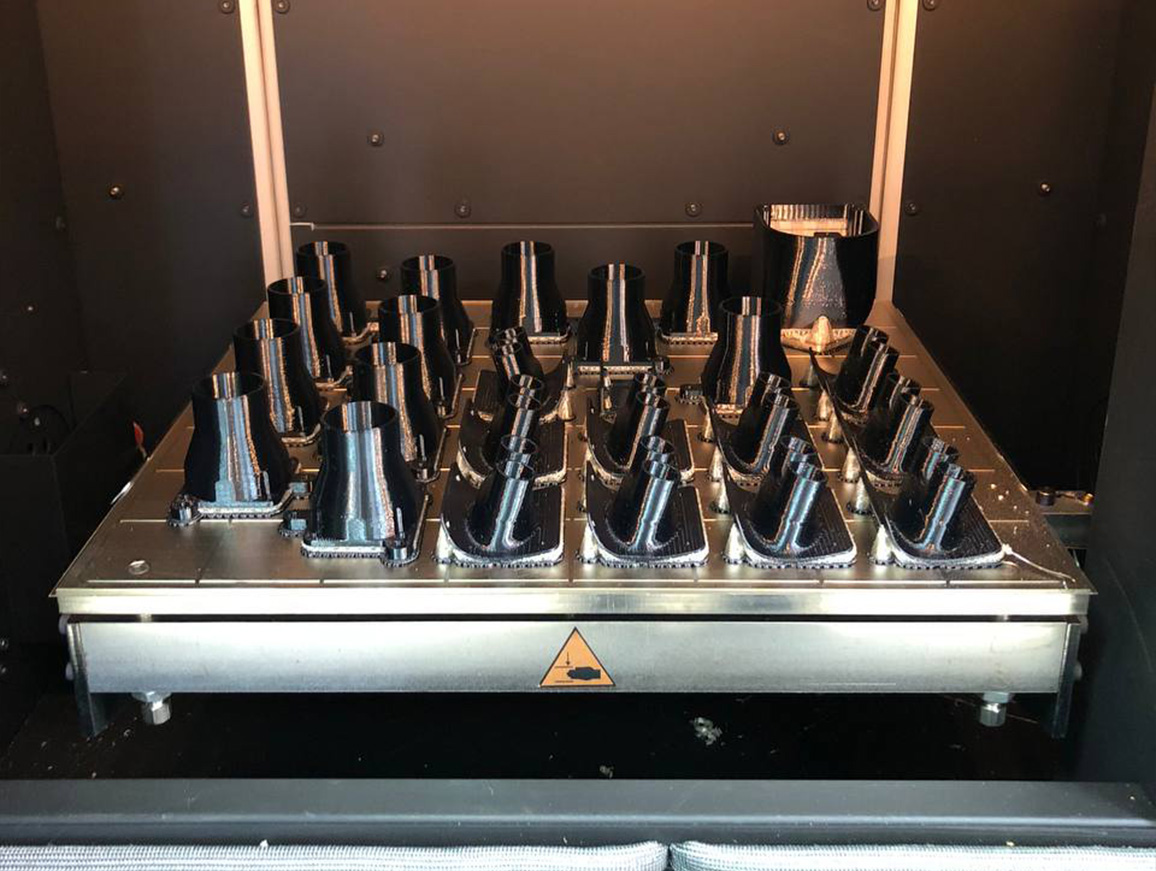

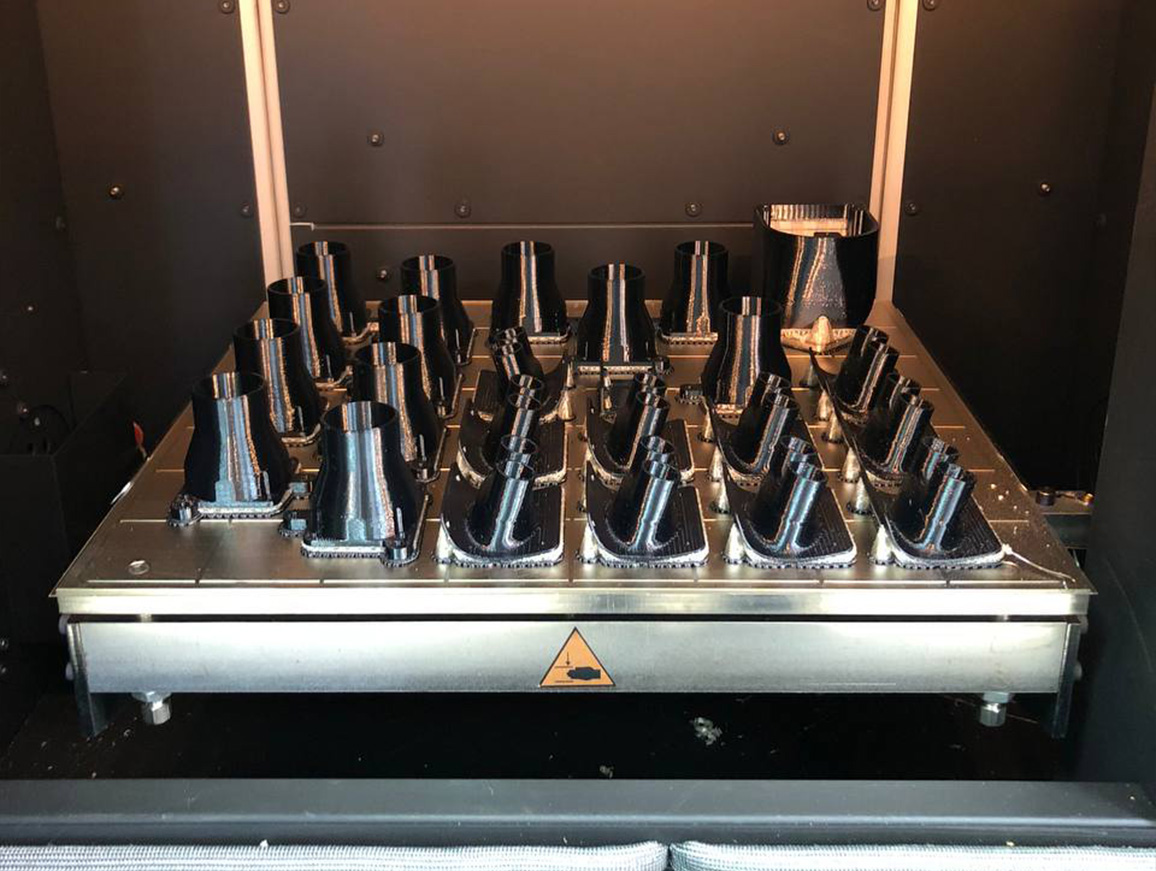

3D Printing

Service

Service

Our industrial 3D printers offer the ability to quickly produce prototypes and productions, both small and large, being able to choose from a wide range of materials, from polymers to metals, and a variety of printing technologies (MJF, SLM, FDM, FFF, SLA, Polyjet), and we are able to produce quality parts in competitive times.

R&D

The R&D team is constantly working to develop new insights into 3D printing technologies and test new materials and processes. We work closely with universities, research institutes and industrial partners to stay ahead of the curve.

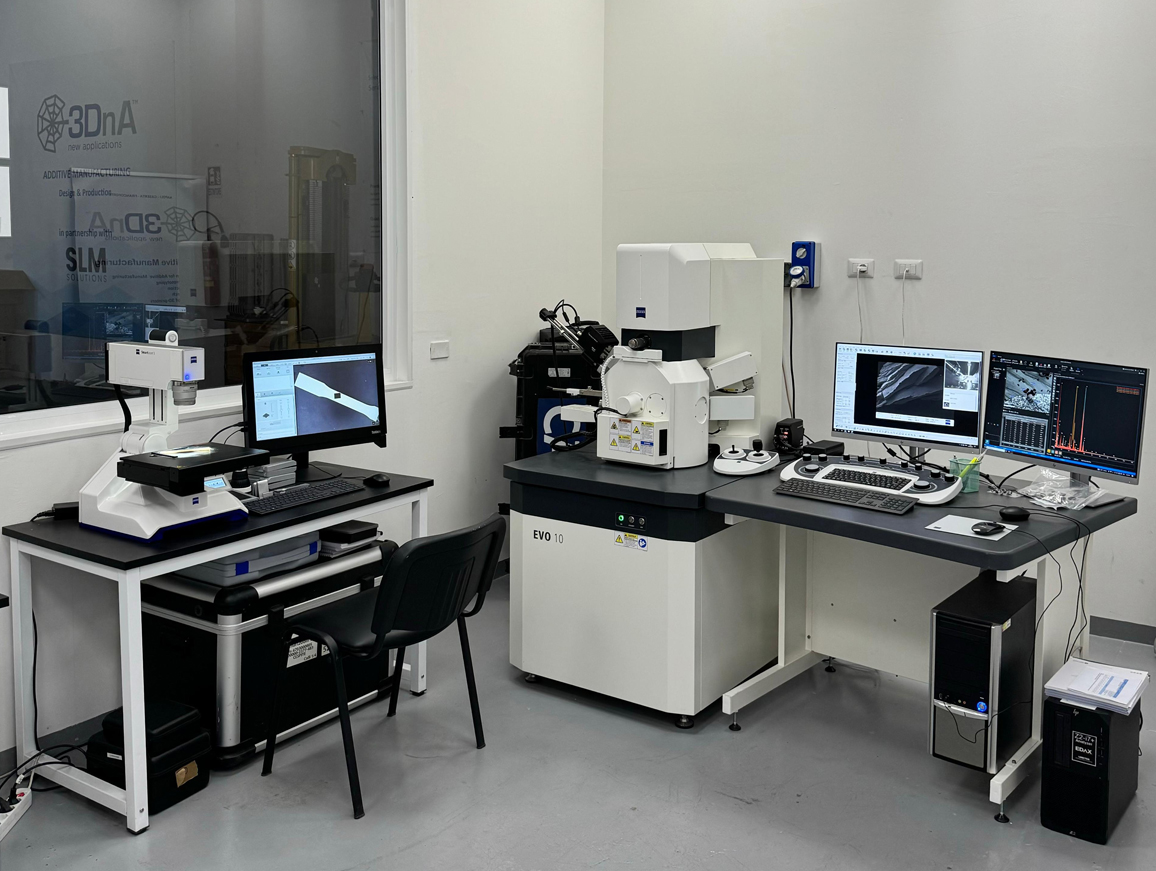

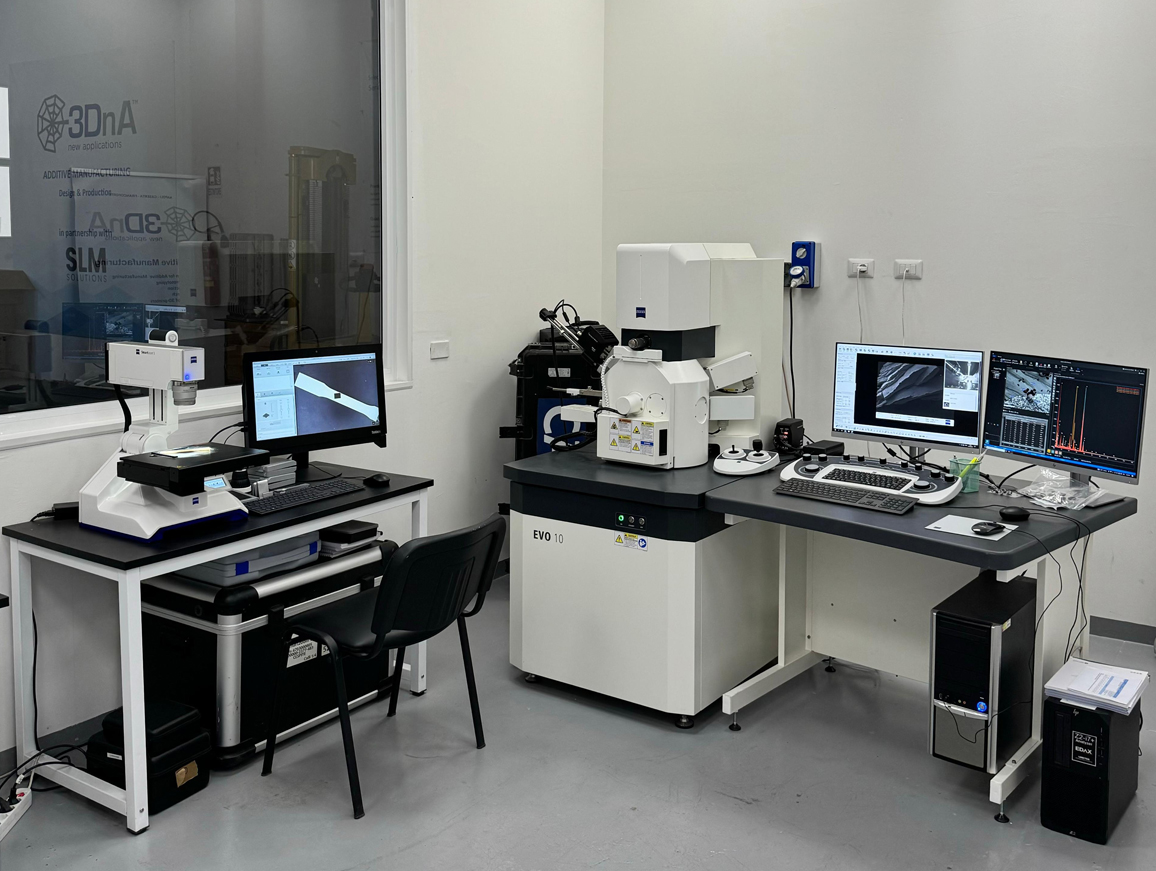

Analysis laboratory for additive manufacturing

The 3DnA Additive Manufacturing analysis laboratory is a cutting-edge center dedicated to the control and verification of additive manufacturing technologies. Equipped with the latest generation equipment, the laboratory includes optical and electronic microscopes for the detailed analysis of materials and surfaces. Furthermore, it is equipped with anthropomorphic arms for laser scanning, which allow precise measurement and digitization of objects. This highly technological environment allows 3DnA to offer advanced solutions for the continuous improvement of additive manufacturing processes, guaranteeing high standards of quality and precision.

- Metal powder analysis

- Mechanical tests

- Material humidity tests

- Dimensional quality control

- Reverse Engineering

- Visual inspection with electron microscope