Technology and

Materials

Materials

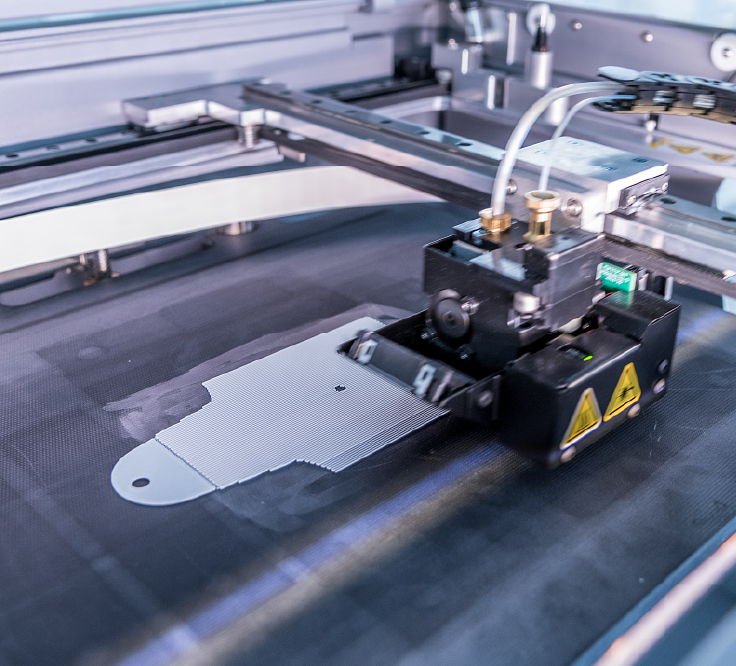

FDM technology enables the creation of complex parts with good resolution and low cost, using thermoplastic filaments. FFF is appreciated for its wide range of materials and for producing low-cost prototypes and functional objects. CFF technology combines thermoplastic filaments with continuous fibers to achieve strength and rigidity similar to metals, suitable for applications requiring high resistance.

PolyJet offers high resolution, smooth surface finish and the ability to use multiple materials and colors in the same print. It is ideal for rapid prototyping, product design, dentistry, model making, and applications requiring accurate detail and customization.

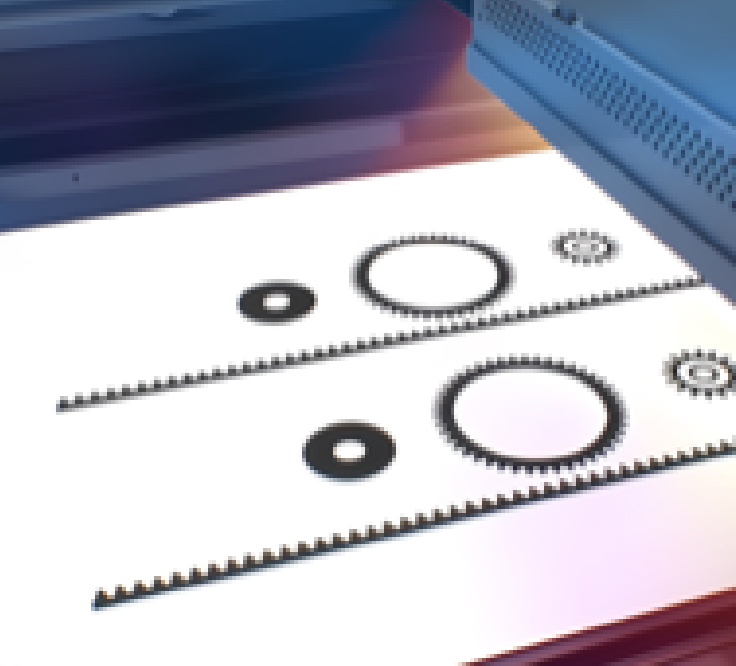

MJF produces three-dimensional objects with high precision and strength, ideal for functional prototypes, production components, and custom objects.

SLM is suitable for manufacturing metal components with complex geometries, such as aircraft parts, medical implants and high-performance automotive components.

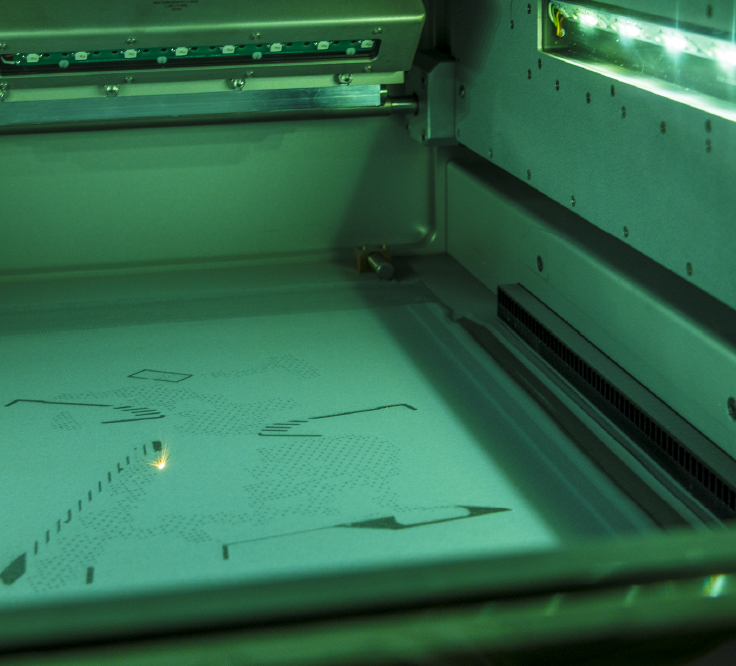

SLA is known for high precision and surface quality, ideal for high-quality prototypes, jewelry, dental models and small parts.

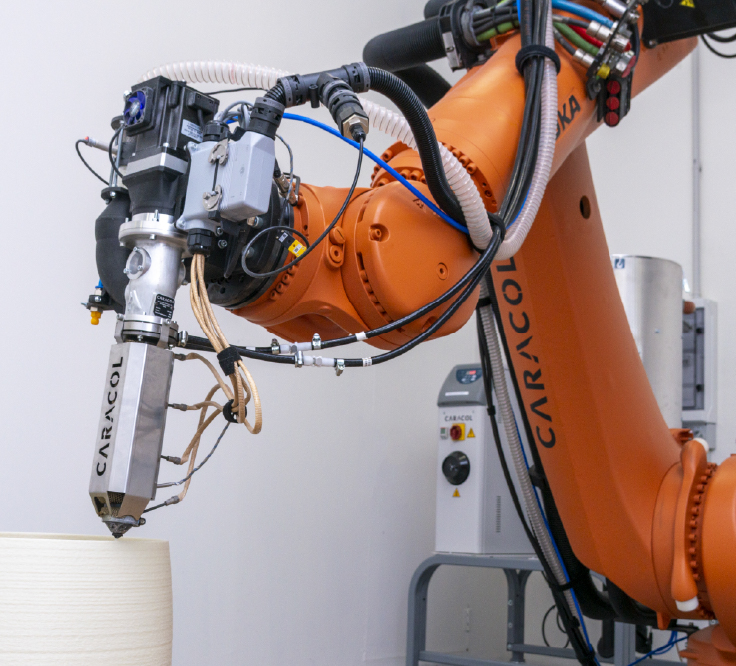

LSAM uses industrial-scale thermoplastic extrusion to produce large items, ideal for industries such as aerospace, marine, energy and construction. It uses high-performance thermoplastic materials, offering strength and durability.