SLA

Technology and

Materials

Materials

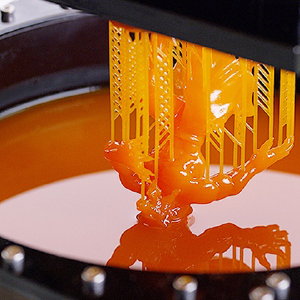

Stereolithography (SLA) is one of the earliest 3D printing technologies, developed by Chuck Hull in 1986.This technology uses an ultraviolet (UV) light source, such as a laser or projector, to harden a liquid photosensitive resin layer by layer.

The hardening process takes place in a resin reservoir, in which the 3D model is gradually lifted as it is completed.

SLA is known for its high precision and surface quality, making it ideal for high-quality prototypes, jewelry, dental models and small parts.

TECHNICAL

Technical resins are formulated to provide specific mechanical properties, such as strength, stiffness, and heat resistance. They are suitable for engineering applications and functional prototyping.

TRANSLUCENT

Translucent resins offer some transparency, allowing the creation of semi-transparent objects or objects with interesting visual effects. They are ideal for applications requiring the visualization of liquid flow or the creation of art pieces.

FLEXIBLE

Flexible resins are designed to create objects with some flexibility and impact resistance. They are suitable for creating flexible components such as seals, grommets or parts that require some elasticity.

AESTHETICS

Aesthetic resins are formulated to provide a high-quality final appearance, with precise details and a smooth surface finish. They are ideal for design prototypes, architectural models and art pieces.

Technology and

Materials

Materials